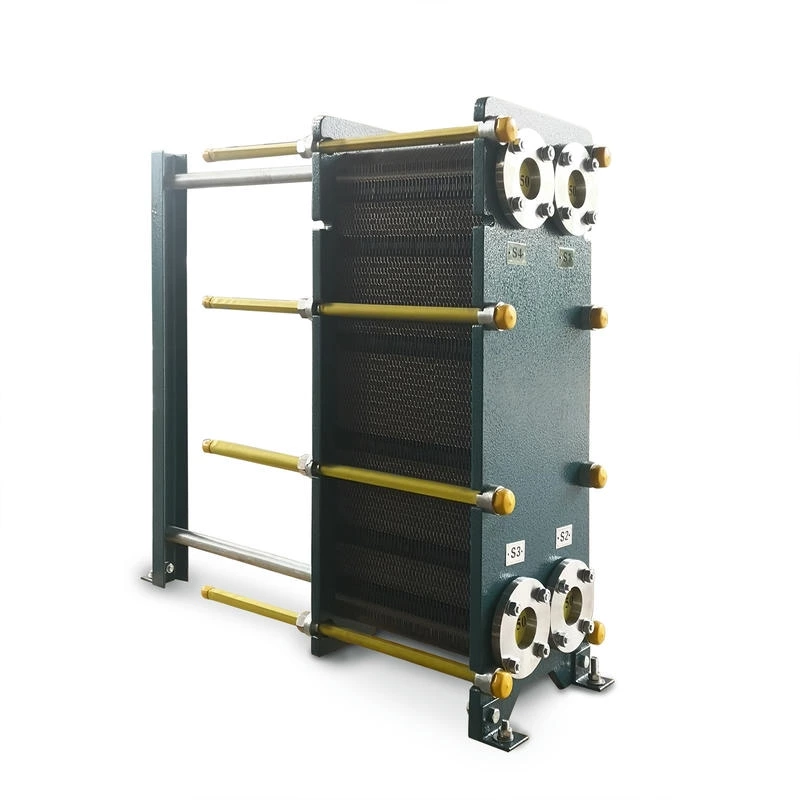

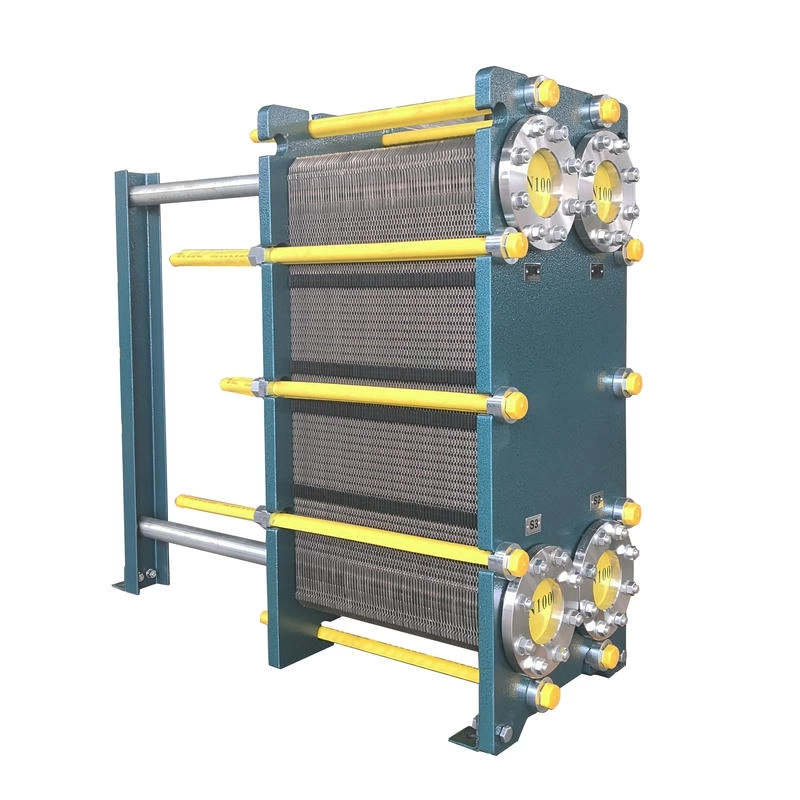

The plate heat exchanger forms a heat transfer channel by superimposing multiple layers of corrugated metal plates, and realizes heat exchange between cold and hot fluids by using complex flow channels formed between plates.

The plate heat exchanger forms a heat transfer channel by superimposing multiple layers of corrugated metal plates, and realizes heat exchange between cold and hot fluids by using complex flow channels formed between plates.

The plate heat exchanger forms a heat transfer channel by superimposing multiple layers of corrugated metal plates, and realizes heat exchange between cold and hot fluids by using complex flow channels formed between plates.

The plate condenser is formed by overlapping multiple layers of corrugated metal plates, and a narrow flow channel is formed between the plates for alternating passage of cold and hot media.

Plate evaporator uses corrugated plates as heat transfer elements, and heat exchange is carried out through the flow channels between plates to realize evaporation and concentration of feed liquid.

Plate evaporator uses corrugated plates as heat transfer elements, and heat exchange is carried out through the flow channels between plates to realize evaporation and concentration of feed liquid.

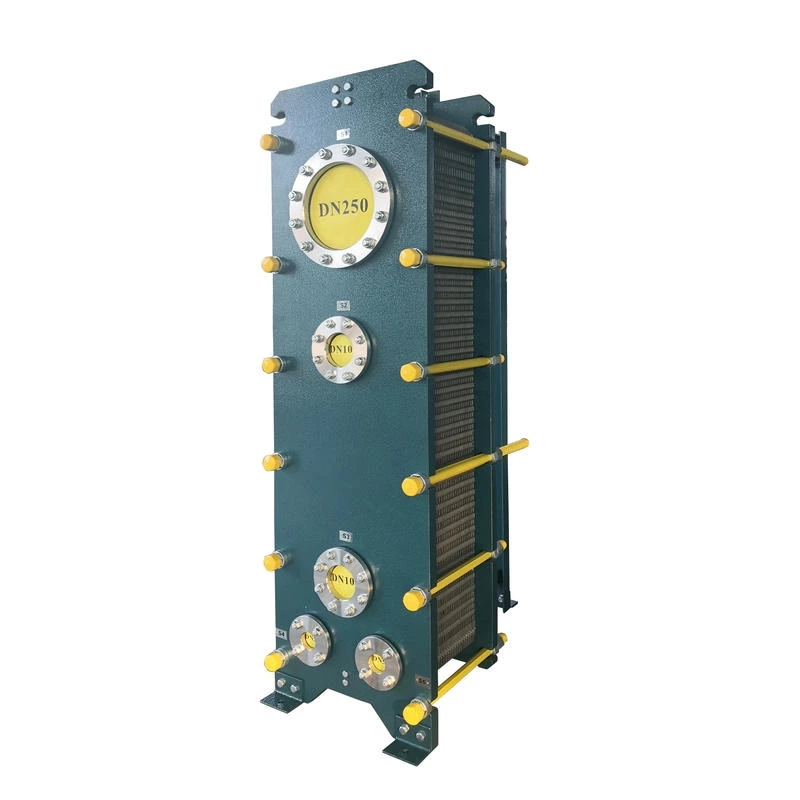

The wide-channel plate heat exchanger is specially optimized for handling media with high viscosity, containing particles or fibers, as well as fluids prone to scaling. The application limitations of ordinary plate heat exchangers under complex working conditions have been solved through a unique flow channel structure

The wide-channel plate heat exchanger is specially optimized for handling media with high viscosity, containing particles or fibers, as well as fluids prone to scaling. The application limitations of ordinary plate heat exchangers under complex working conditions have been solved through a unique flow channel structure

The core structure of the spiral plate heat exchanger is composed of two parallel metal plates rolled into concentric spiral channels. The cold and hot fluids flow in opposite directions in adjacent channels respectively and exchange heat through the plate walls. It is widely applied in fields such as chemical engineering, petroleum, pharmaceuticals, food, energy and environmental protection.

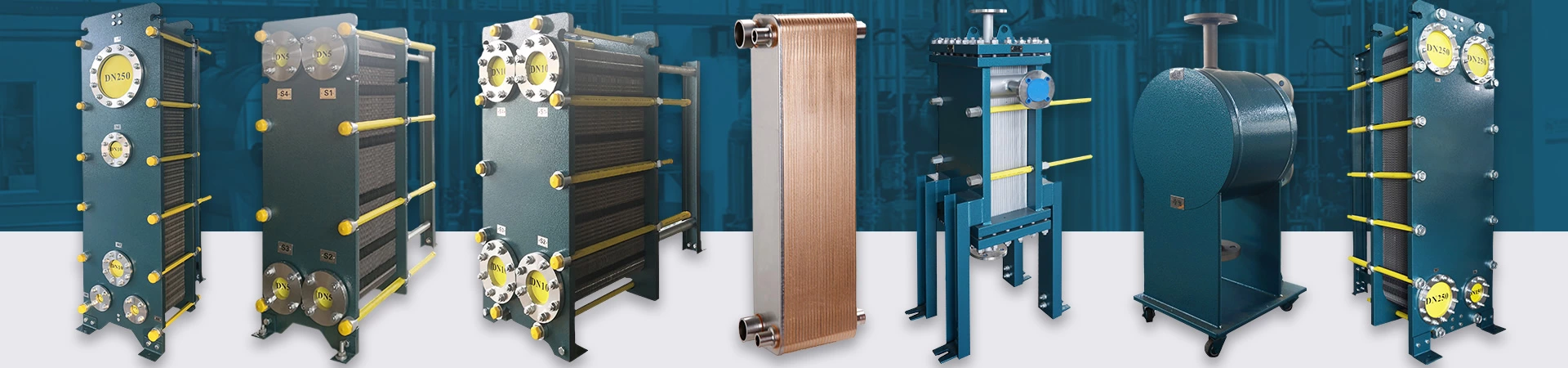

INTRODUCTION

FLYH provides you with a full range of heat exchange solutions

The corrugated plate design enhances turbulence, and the heat transfer efficiency is 3-5 times that of traditional heat exchangers. A small temperature difference can efficiently recover energy and reduce energy consumption by 15%-30%.

The volume is 60%-80% smaller than the shell and tube type. The modular design allows flexible addition and subtraction of plates, saves space and is suitable for complex installation environments (such as ships and factories)

The single piece can be quickly disassembled for cleaning or replacement. The gasket early warning system reduces the risk of leakage, and the maintenance cost is more than 60% lower than that of traditional equipment.

WRITE TO US

Don't hesitate to contact us. FLY HIGH TRADING L.L.C experts are very happy to help you, provide a variety of flexible and reliable solutions to help you solve various problems.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details