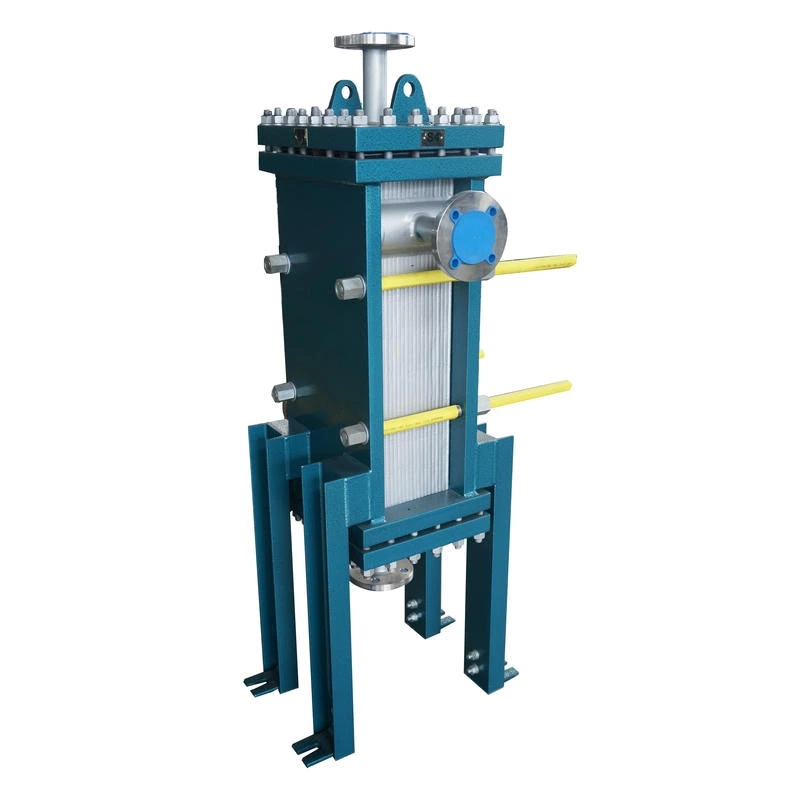

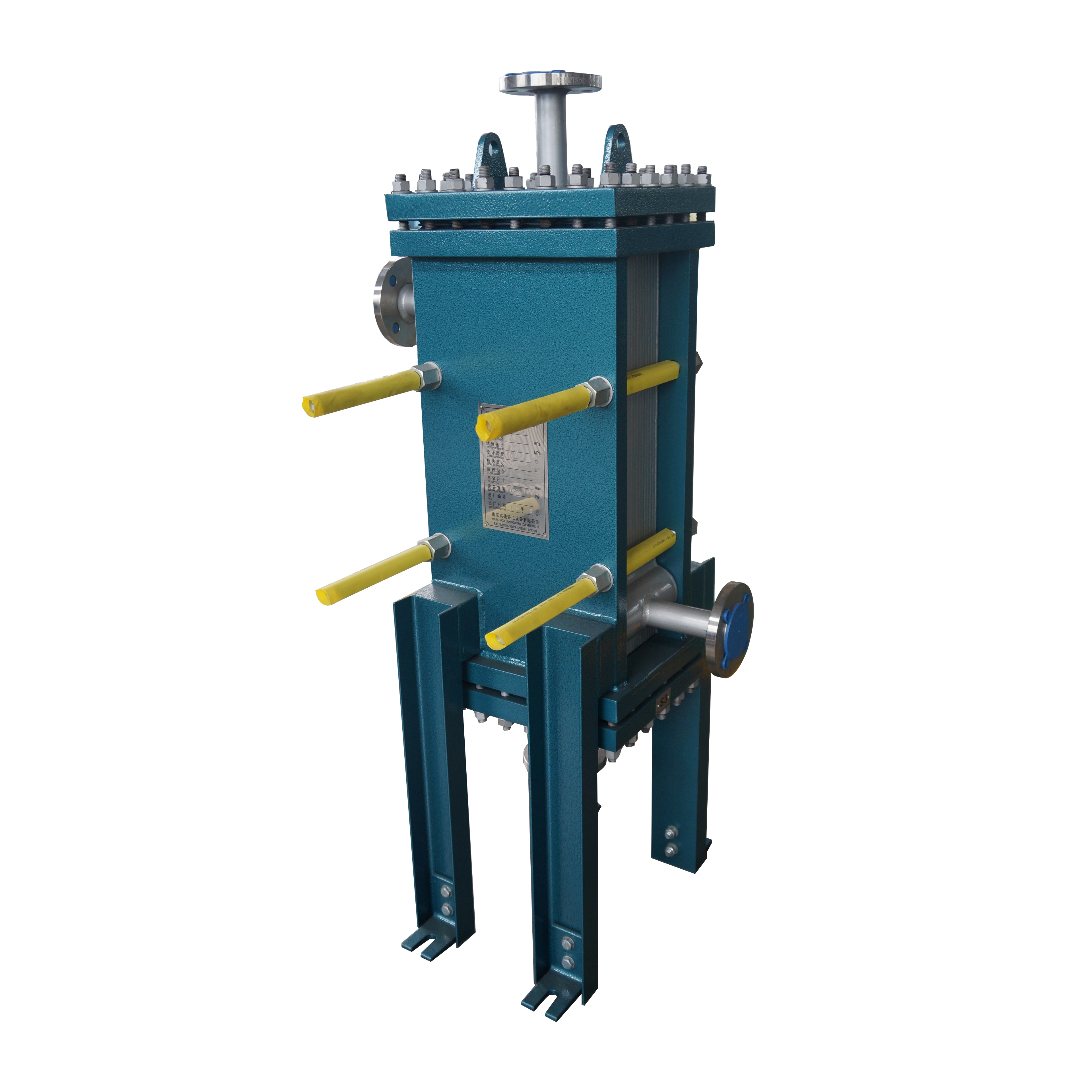

The fully welded plate heat exchanger and the conventional detachable plate heat exchanger are two common types of plate heat exchangers. They differ significantly in terms of structure, performance, and application scenarios. Here are the main differences between them:

1. Structural Design

The plates of the fully welded plate heat exchanger are permanently fixed by welding, forming an inseparable integrated structure. There are no sealing gaskets, and all flow channels are sealed by welding. Usually, laser welding or brazing techniques are adopted, resulting in greater overall rigidity.

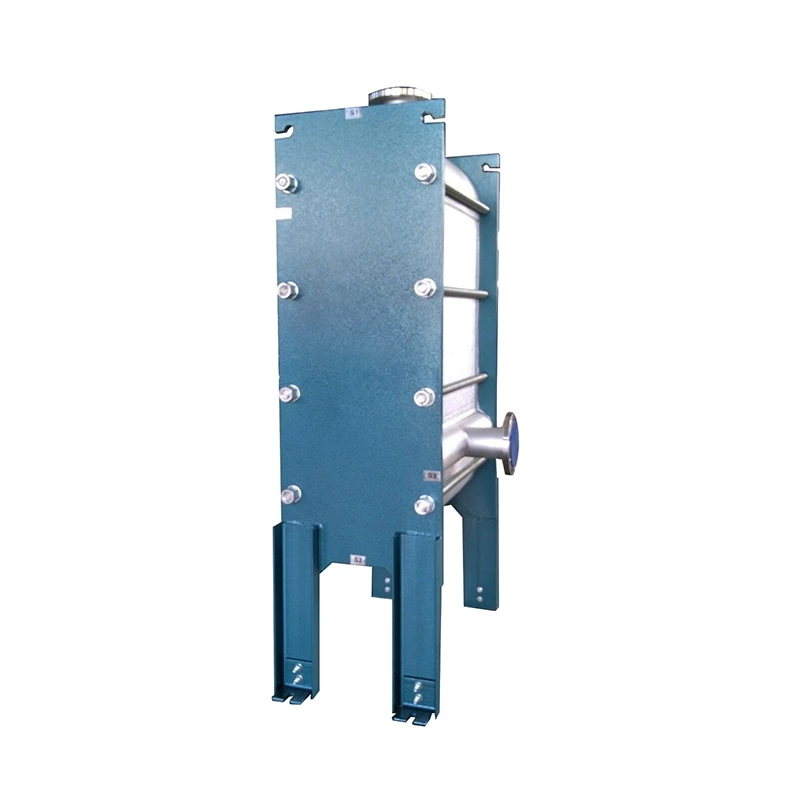

The detachable plate heat exchanger plates are assembled by pressing with bolts, allowing for disassembly for maintenance or component replacement. They rely on rubber gaskets (such as NBR, EPDM, etc.) to seal the flow channels, but the gaskets are prone to aging or corrosion.

2. Sealing performance and pressure/temperature resistance capability

The all-welded plate heat exchanger has no gaskets and completely avoids the problem of gasket leakage. It is suitable for high pressure (up to 4.0 MPa or above), high temperature (above 400°C) or extreme conditions (such as strong corrosive media). The welding process requires high standards. If there is an internal leakage, the entire unit needs to be reworked.

The detachable plate heat exchanger relies on gaskets for sealing and has lower pressure resistance (usually ≤ 2.5 MPa) and temperature resistance (generally ≤ 180°C).

Gaskets are susceptible to chemical media and temperature changes and need to be replaced regularly, resulting in high maintenance costs.

3. Maintenance and Cleaning

The fully welded plate heat exchanger is non-detachable and difficult to be mechanically cleaned. Usually, it can only be chemically cleaned or back-flushed. It is suitable for clean media or working conditions where scaling is not likely (such as gases, oils).

The detachable plate heat exchanger can disassemble the plates for mechanical cleaning, and is suitable for media prone to scaling or containing particles (such as cooling water, slurries). The gaskets are easy to replace, and the maintenance cost is low but the frequency is high.

4. Application Scenarios

The fully welded plate heat exchanger is used for high-temperature and high-pressure, corrosive media (such as acids and alkalis), and flammable and explosive fluids (such as liquefied gas and ammonia).

Typical applications: petrochemicals, pharmaceuticals, nuclear power, refrigeration (ammonia system).

The detachable plate heat exchanger is usually applied in HVAC (heating, ventilation, and air conditioning), food and beverage, low-pressure steam heat exchange, and domestic hot water systems.

Suitable for scenarios where frequent cleaning or replacement of the medium is required.

5. Cost and Lifespan

The fully welded plate heat exchanger has a high initial cost (due to the complex welding process), but it has a long service life (without the problem of aging of gaskets), and the overall operating cost may be lower.

The detachable plate heat exchanger has a low initial cost, but it requires regular replacement of gaskets and plates, and the long-term maintenance cost is higher.

6. Compactness and Efficiency

Both offer efficient heat transfer (through the plate-fin design which enhances turbulence). However, the fully welded type does not have the limitations of gaskets, allowing for smaller plate spacings and potentially a more compact volume.

technical specification

| Item |

Value |

Item |

Value |

| Corrugation Angle |

130° |

Corner Hole Diameter (mm) |

Φ146 |

| Corrugation Normal Pitch (mm) |

7.9 |

Plate Blanking Size (mm) |

870×870×0.8 |

| Corrugation Depth (mm) |

6.4 |

Single Plate Area (m²) |

0.52 |

| Equivalent Diameter (mm) |

11.5 |

Plate Outer Dimensions (mm) |

Φ855 |