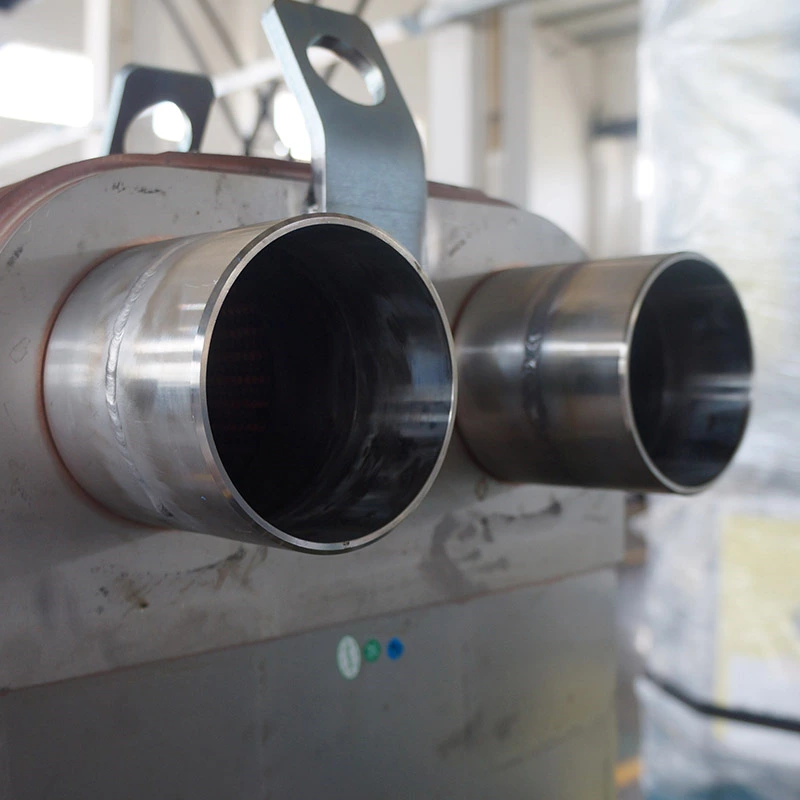

Brazed Plate Heat Exchangers GJ52

The brazed plate heat exchanger is permanently connected by multiple layers of stainless steel plates through the brazing process. Its core structure consists of corrugated plates, brazing materials (usually copper or nickel), and an external frame. The corrugated design between the plates forms complex flow channels, allowing cold and hot media to flow in opposite or cross directions in adjacent channels, achieving rapid heat exchange.

Characteristics

High-efficiency heat transfer

The corrugated plate design enables the heat transfer coefficient to reach 3 to 5 times that of shell and tube heat exchangers, significantly enhancing energy efficiency.

Compact and lightweight

Its volume is only 20%-30% of that of traditional heat exchangers, saving installation space.

Pressure and temperature resistance

The brazed structure can withstand a pressure of over 30 bar and a temperature range of -160℃ to 220℃ (depending on the brazing filler metal).

Long service life and maintenance-free

Gasless design avoids leakage risk, and corrosion-resistant materials (such as 316L stainless steel) extend service life.

Versatility

Applicable to liquid-liquid, gas-liquid and phase change heat transfer (such as evaporation or condensation).