Plate condensers and plate heat exchangers are similar in structure and principle, both using metal plates stacked to form flow channels for heat exchange. However, depending on the application scenarios and functional requirements, there are the following key differences

1、Function and Application

Plate condensers (specialized type) are specifically designed for the condensation process, which involves cooling gaseous media (such as refrigerants, steam) and converting them into liquid.

Plate heat exchangers (general-purpose) are used for heat exchange between liquids and liquids or between liquids and gases, with no phase change or only single-phase heat exchange.

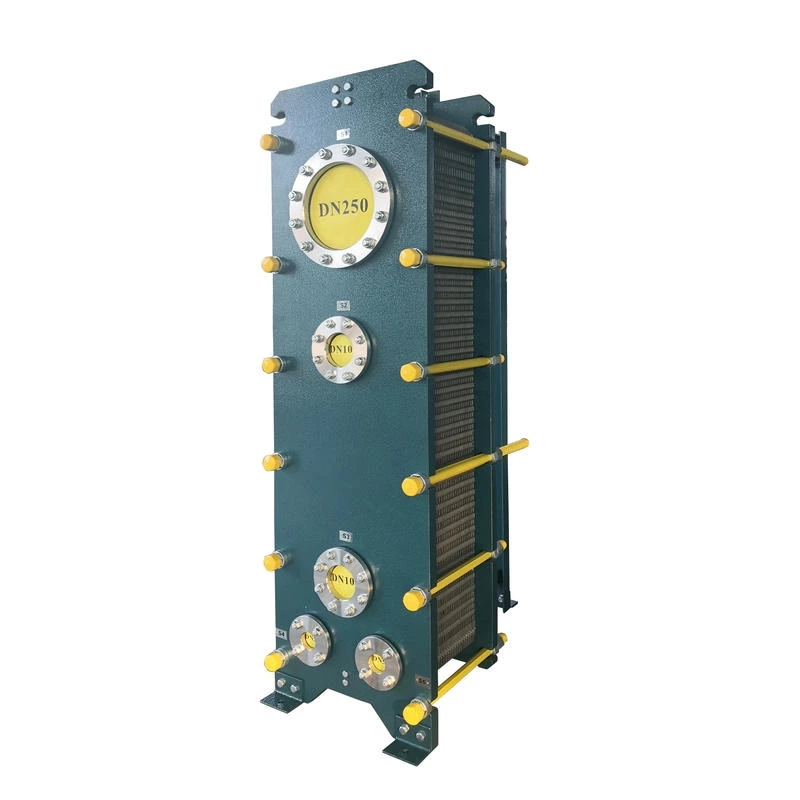

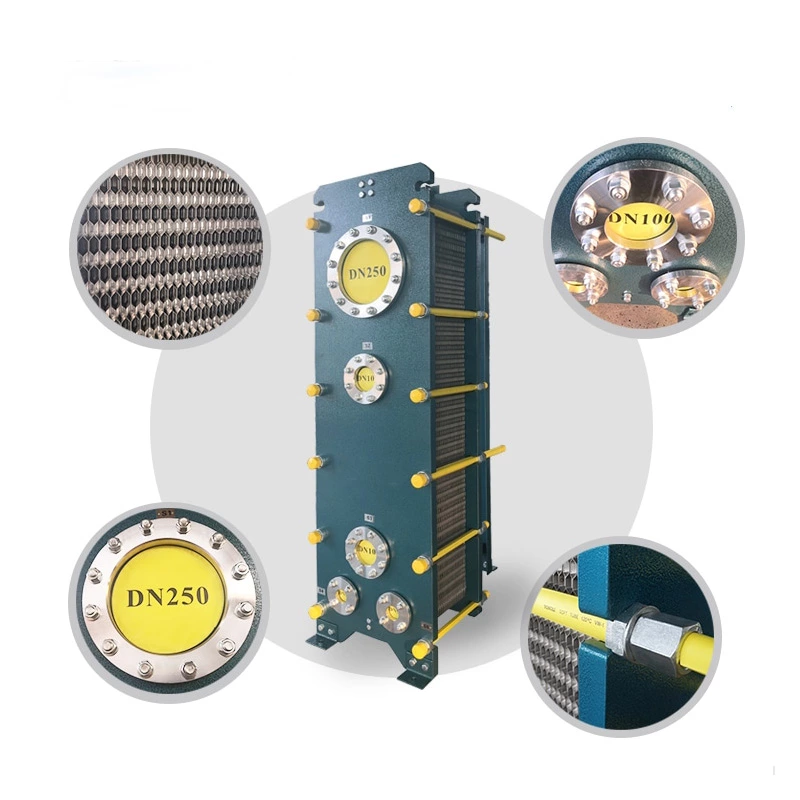

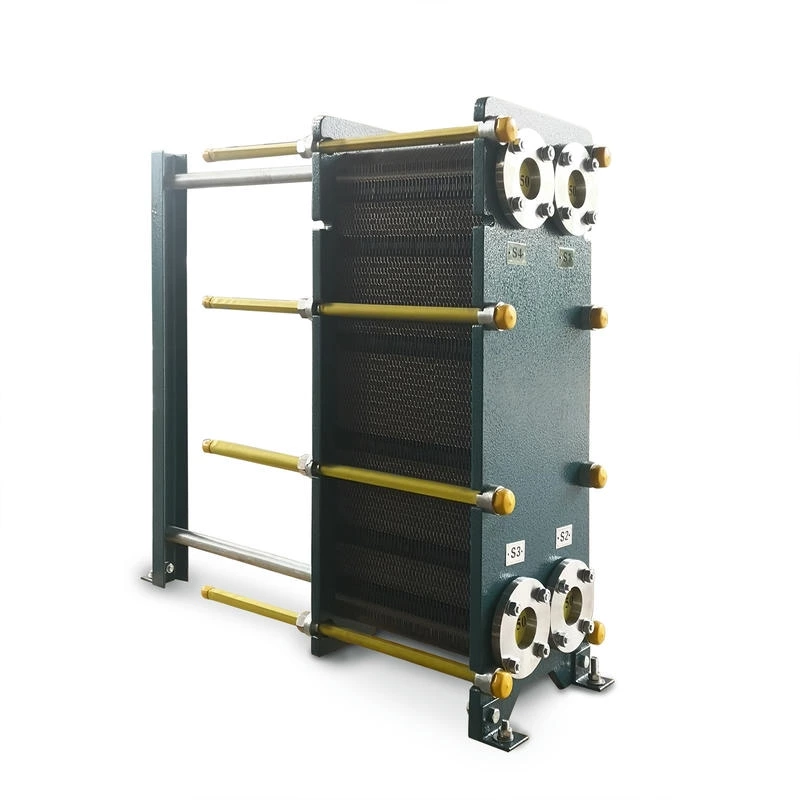

2、Design and structural differences

Plate condensers may adopt asymmetric flow channels (such as a combination of wide and narrow channels) to optimize the distribution of gas-liquid two-phase flow and the discharge of condensate. And it needs to withstand higher pressure (especially on the refrigerant side), and the sealing requirements are stricter

Plate heat exchangers are usually symmetrical flow channels, emphasizing uniform fluid distribution and enhanced turbulence. It has a wide range of pressure adaptability. Just select the sealing material according to the medium.

3、Medium and Working Conditions

The plate condenser processes media from gas to liquid (such as refrigerant R134a, ammonia vapor). The inlet is high-temperature gas (if the refrigerant can reach above 80℃), and the outlet is low-temperature liquid.

The medium processed by the plate heat exchanger is single-phase fluid (such as water-water, water-oil), and the temperature can be flexibly adjusted according to the application without the need for phase change.

4.Material selection and maintenance

The material of the plate condenser should be corrosion-resistant (such as if the refrigerant may contain acidic impurities) and high-pressure resistant (such as titanium plates used in ammonia systems). During maintenance, attention should be paid to the residual condensate and scaling issues

Plate heat exchangers offer a wider range of material options (such as stainless steel and graphite), with a focus on medium compatibility.

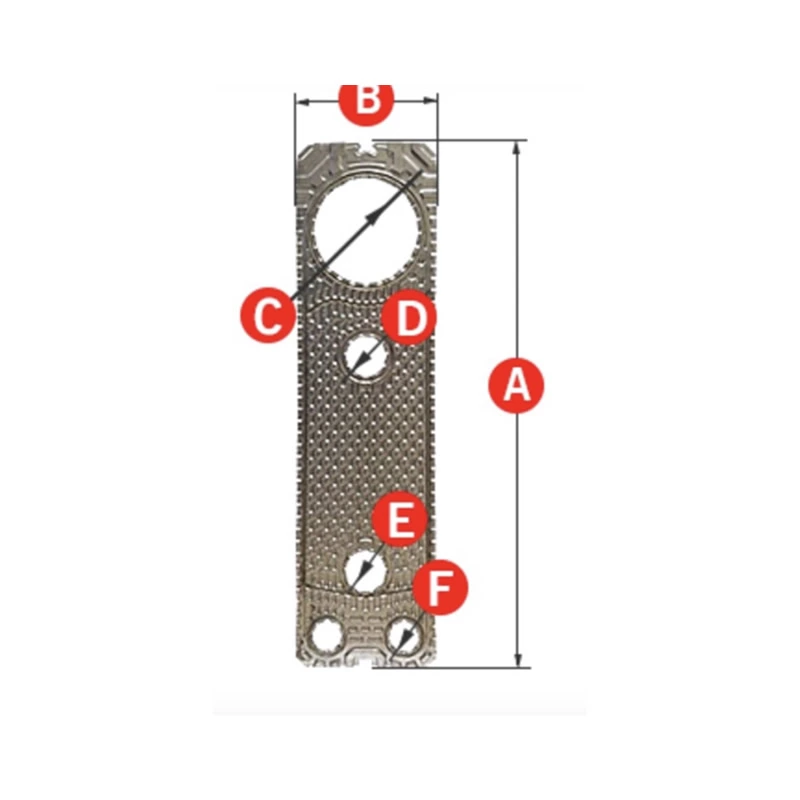

| Model |

Single Plate Area (m²) |

Overall Dimensions (mm) |

Corner Hole Diameter C |

Corner Hole Diameter D |

Corner Hole Diameter E |

Corner Hole Diameter F |

| L400 |

0.45 |

1835×489 |

Φ372 |

Φ150 |

Φ150 |

Φ100 |