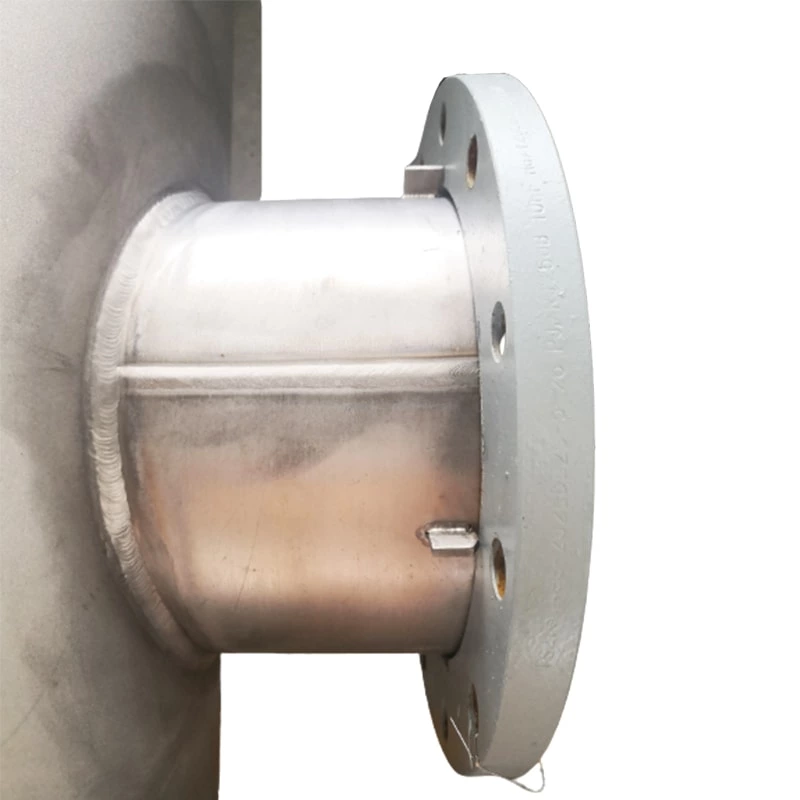

Shell and tube heat exchanger GJ-LG20

Shell and tube heat exchangers are one of the most widely used heat exchange devices in the industrial field. They have reliable structures and strong adaptability, and are suitable for high-temperature, high-pressure and high-flow working conditions. Its core design is composed of components such as the shell, tube bundle, tube sheet and baffle plate

Characteristics

Modular Construction

It consists of components such as the shell, tube bundle, tube sheet, baffle, and head. Each component can be independently designed or replaced (for example, changing the material of the tube bundle to adapt to different media), facilitating maintenance and customization.

Multi-process Configuration

Through the use of process separation baffles, multiple process combinations for the tube side (tube side) and the shell side (shell side) can be achieved (such as types 1-2, 2-4). The fluid path and flow rate can be flexibly adjusted to optimize heat transfer efficiency.

Balance between Compactness and Expandability

The heat transfer area per unit volume is large, and the capacity can be expanded by increasing the length or quantity of the tube bundle. It is suitable for both small-scale and large-scale industrial applications.

Energy Efficiency and Resistance Balance

The ratio of pressure drop to heat transfer can be optimized by adjusting the pipe diameter, arrangement method (triangle/square), and baffle spacing (for example, the pressure drop in the shell side is usually 10-50 kPa).