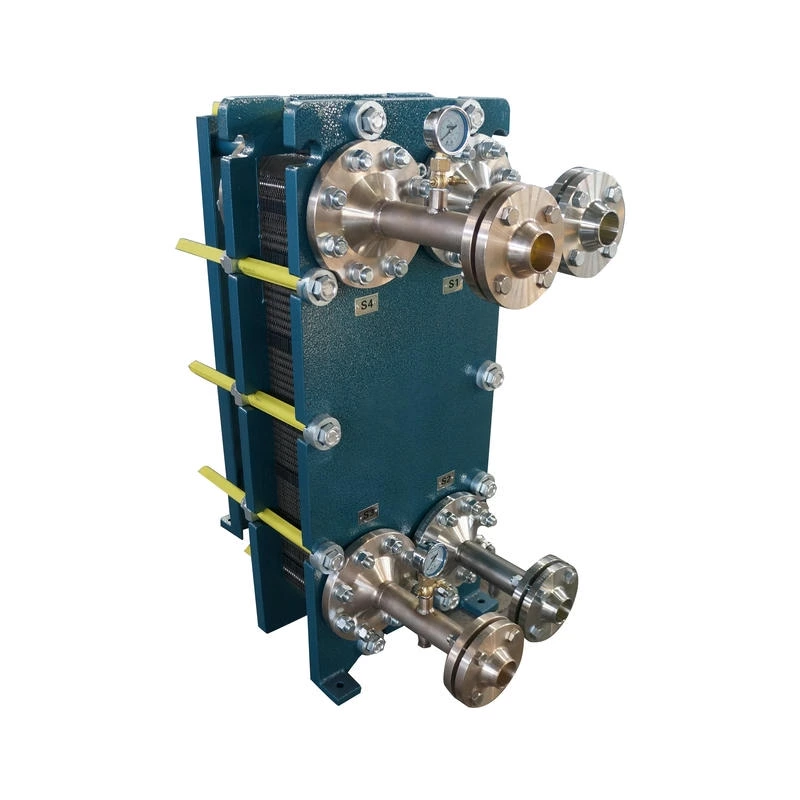

Semi-welded plate heat exchanger T20MW

Semi-welded plate heat exchangers are a compromise between detachable plate heat exchangers and fully welded plate heat exchangers. They feature a partially welded and partially detachable design, offering both high sealing performance and certain maintenance flexibility.

Characteristics

Enhanced high-pressure and temperature resistance

The welding side can withstand higher pressure (typically 2.5 - 4.0 MPa) and temperature (200 - 300℃), which is more stable compared to the full gasket type.

The welding channel is suitable for volatile, toxic or expensive media (such as ammonia, refrigerants, chemicals), preventing the risk of leakage.

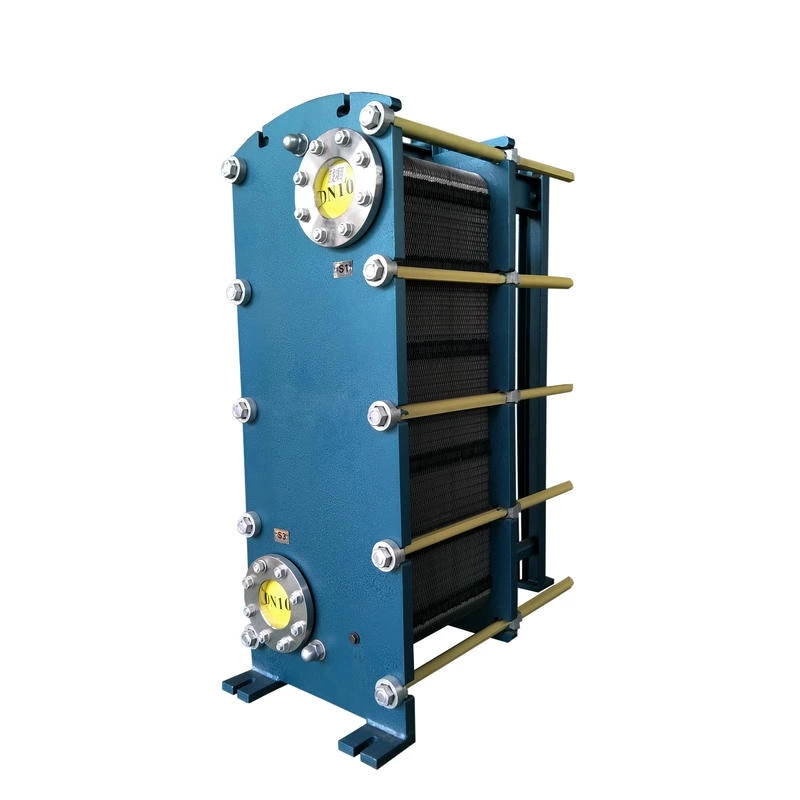

Maintain flexibility

The sealing side of the gasket can still be disassembled, facilitating cleaning, inspection or replacement of the plates, thereby reducing maintenance costs.

It is suitable for media prone to scaling or containing particles (such as industrial wastewater, viscous liquids), and can be mechanically cleaned regularly.

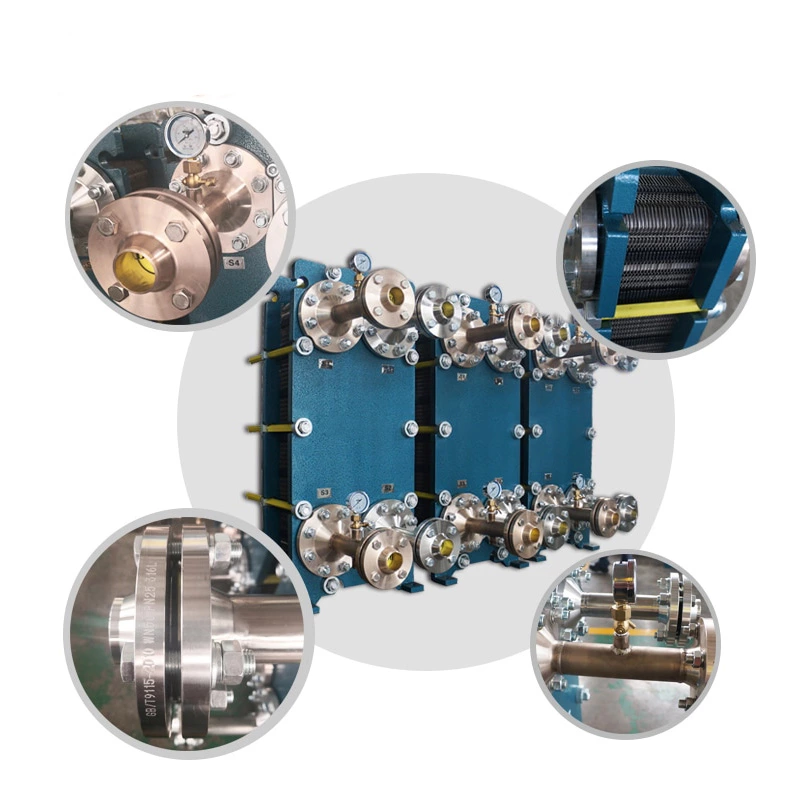

Corrosion Resistance

The welding side can use corrosion-resistant alloys (such as titanium, nickel-based alloys), while the gasket side uses corrosion-resistant elastomers (such as EPDM, fluororubber).

This avoids the risk of the entire welded structure being completely damaged under strong corrosive media, resulting in better economic benefits.

Compact and Efficient

The plate heat exchanger retains its high heat transfer efficiency (with a K value reaching up to 6000 W/m²·K), and its volume is only 1/3 to 1/5 of that of a shell-and-tube type.

The corrugated plate design enhances turbulence and reduces fouling, making it suitable for medium-cleanliness media.

Flexible configuration

It can be designed as "single-sided welding" (only one medium passes through the welding side) or "bilateral welding" (both media are enclosed), meeting the requirements of different working conditions.

It supports multi-process design and can handle heat exchange scenarios with large temperature differences or flow rate mismatches.