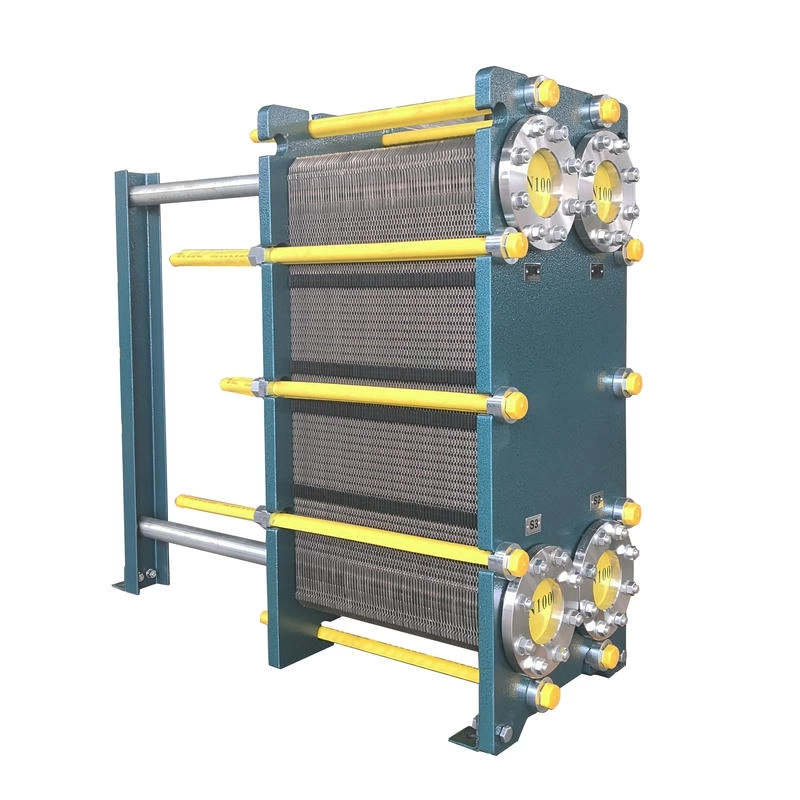

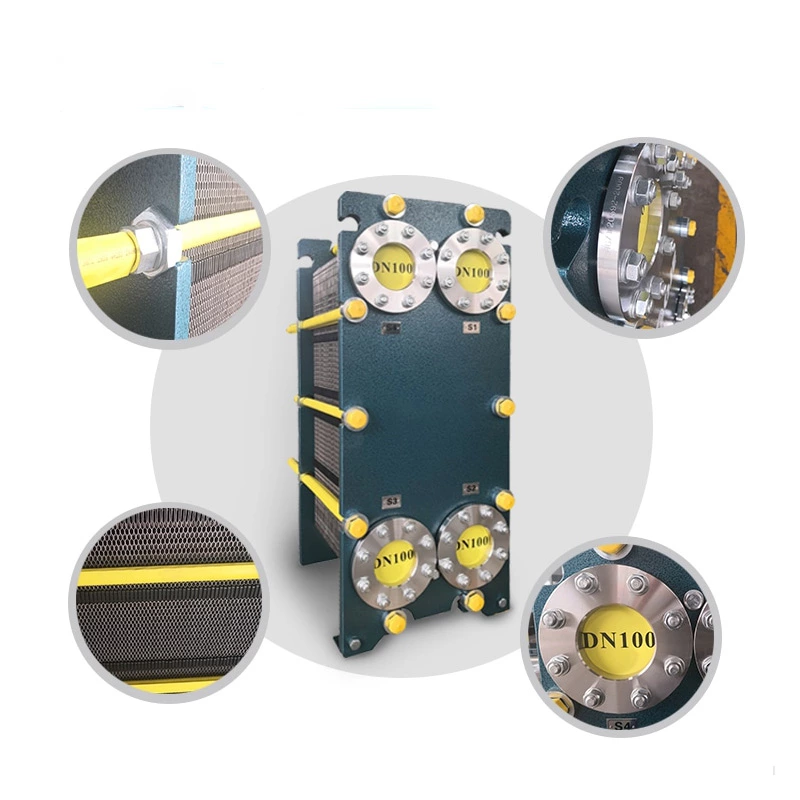

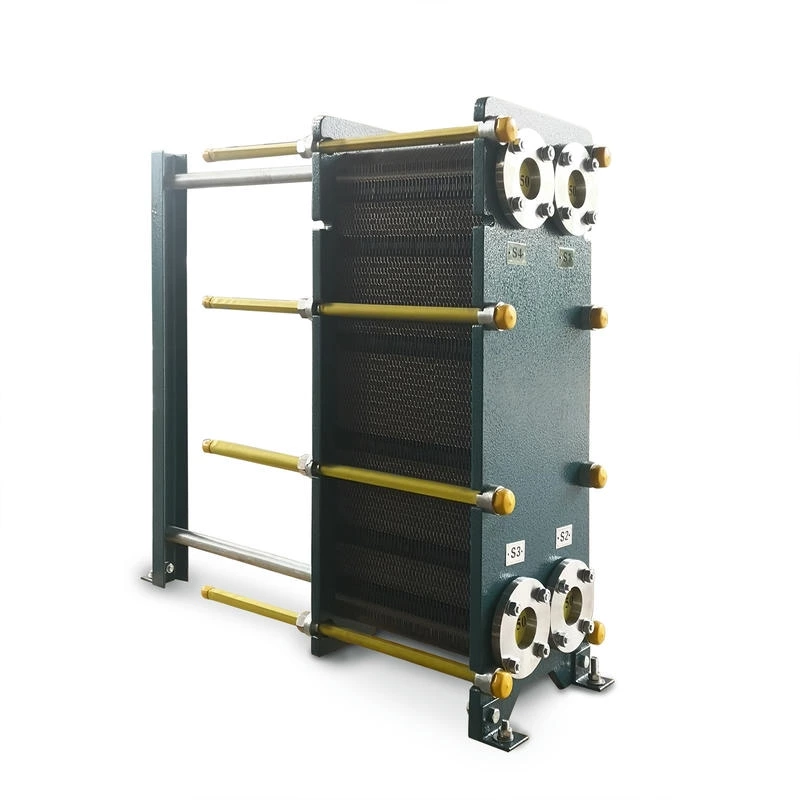

Wide Channel Plate Heat Exchanger BW100A

The wide-channel plate heat exchanger is specially optimized for handling media with high viscosity, containing particles or fibers, as well as fluids prone to scaling. The application limitations of ordinary plate heat exchangers under complex working conditions have been solved through a unique flow channel structure

Characteristics

Wide-spaced flow channel design

The width of the flow channel can reach 2-5 times that of conventional plate heat exchangers, significantly reducing flow resistance and preventing particle or fiber accumulation and blockage. It is suitable for slurries, sludges, syrups, etc., which are high-viscosity or contain impurities.

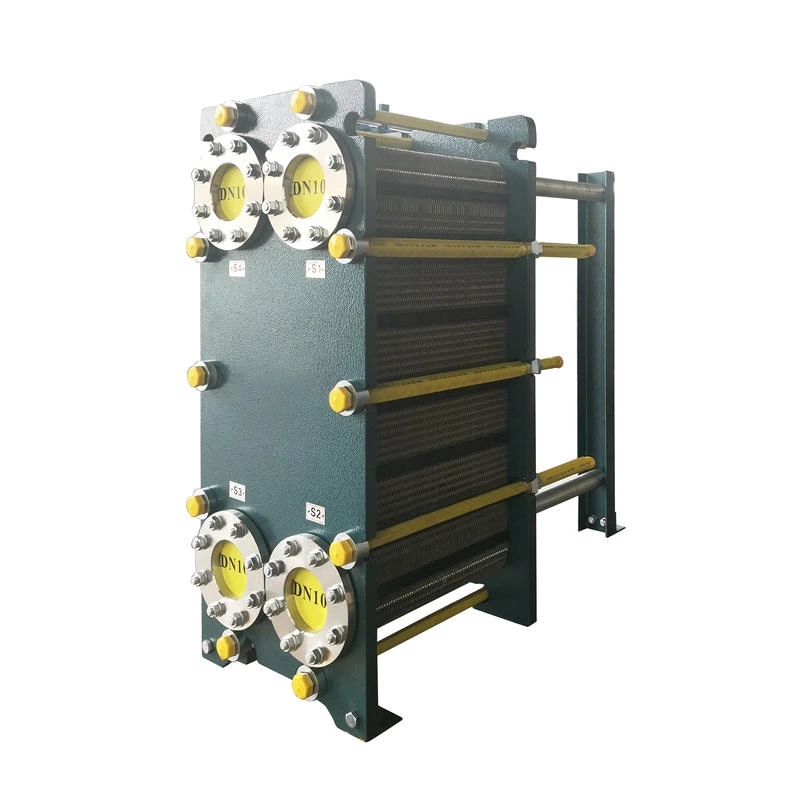

Enhanced heat transfer technology

Special stamping processes (such as inclined waves, spherical protrusions, etc.) are adopted for the corrugated plates, ensuring a turbulent state even when the flow channel is widened. The heat transfer coefficient can reach 3-5 times that of shell-and-tube heat exchangers.

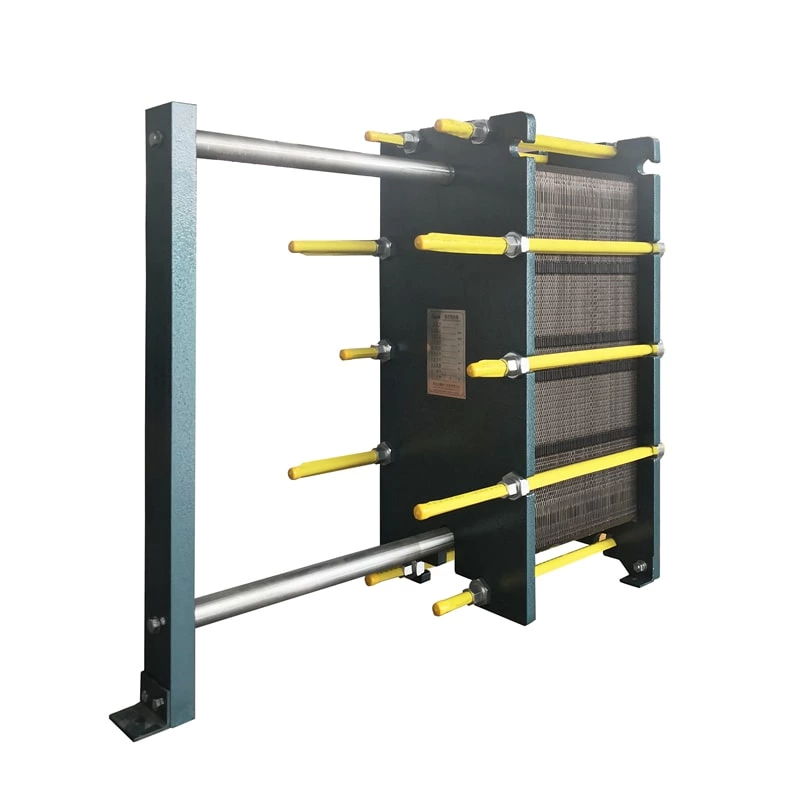

Anti-scaling and ease of maintenance

The large flow channel reduces the retention area, combined with the detachable plate structure, facilitates mechanical cleaning or chemical cleaning, significantly extending the maintenance period and reducing downtime costs.

Material and seal compatibility

Available in stainless steel, titanium, Hastelloy, etc. The sealing gasket has a wide temperature range (-40℃ to 200℃), suitable for corrosive media or high-temperature conditions.