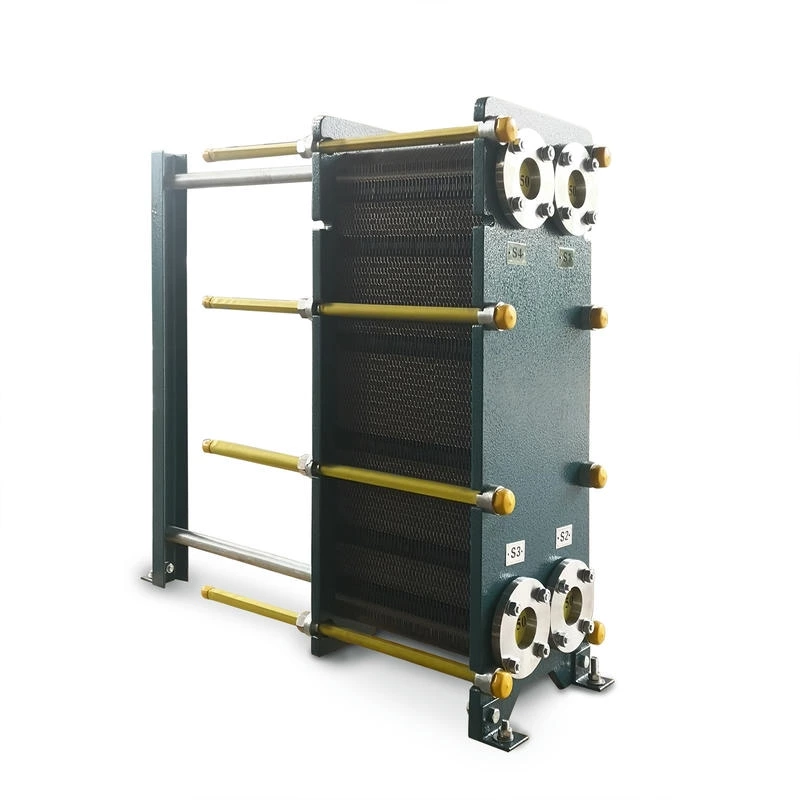

Spiral plate heat exchanger GJ-LXB

The core structure of the spiral plate heat exchanger is composed of two parallel metal plates rolled into concentric spiral channels. The cold and hot fluids flow in opposite directions in adjacent channels respectively and exchange heat through the plate walls. It is widely applied in fields such as chemical engineering, petroleum, pharmaceuticals, food, energy and environmental protection.

Characteristics

Spiral Plate Group:

Two steel plates are rolled to form two sets of spiral channels. The channel spacing is supported by spacer columns to ensure uniform fluid distribution and structural stability.

Sealing Design:

The ends of the channels are sealed by welding or gaskets to prevent fluid leakage. Different materials (such as stainless steel, titanium alloy, etc.) can be selected based on the medium characteristics.

Inlet and Outlet Configuration:

Cold and hot fluids enter from the tangential inlet on both sides of the spiral body and flow along the spiral path, prolonging the heat exchange time and improving efficiency.

Double Channel Design:

The two fluid channels are separated by spacer columns welded during the rolling process or a special structure during rolling to avoid cross-contamination.

Shell:

A cylindrical shell wraps the spiral plates, with both ends sealed. It is usually designed as detachable for cleaning.

Inlet and Outlet Connectors:

Located at both ends of the spiral channels, the fluid flows in/out from the center or is distributed along the periphery, depending on the flow direction (full counter-flow or cross-flow).